Blog Articles

The Historical Evolution and Industrial Transformation of DEA by NETZSCH and sensXPERT

In today’s fast-paced industrial environment, particularly within the plastics and composites manufacturing sectors, ensuring product quality and optimizing manufacturing processes are essential. Manufacturers in these fields face unique challenges, such as precisely controlling material properties and promptly responding to process variations. Advanced measurement techniques are crucial to maintaining competitive advantage and operational efficiency in such […]

The Impact of Electric Vehicles on Automotive Plastics

Electric vehicles (EVs) have rapidly evolved from niche products to mainstream transportation options. The first modern, mass-produced electric cars emerged in the early 2000s, and since then, advancements in battery technology, infrastructure, and consumer acceptance have significantly accelerated their adoption. Governments worldwide are promoting EVs to reduce greenhouse gas emissions and dependence on fossil fuels, […]

Data-Driven Optimization in Aerospace Composites Manufacturing

In its continuous pursuit of efficiency and performance, the aerospace industry has increasingly turned to plastic and composite materials. Plastics and composites offer significant advantages over traditional materials like metal. Advanced lightweight plastics and composites translate to improved fuel efficiency, while their design flexibility allows for innovative and aerodynamic shapes with reduced part count. However, […]

The Electric Vehicle Revolution and the Future of Automotive Plastics

The automotive industry is in the midst of a transformative shift. One of the most significant markers of this shift is the swift rise of electric vehicles (EVs). The transition away from traditional internal combustion engines (ICE) is driven by several factors, among them being: This shift necessitates a complete rethinking of car manufacturing. New […]

3 Strategies for Cost-Effective Plastics Manufacturing

Recent years have seen many factors adding significant pressure on the economic viability of plastics manufacturing. Rising costs across the entire value chain threaten to compromise profit margins and hinder the industry’s ability to deliver cost-effective solutions to customers. This article investigates the core economic factors driving cost pressures within plastics manufacturing. One the […]

Inefficient Processes & Supply Chain Disruptions: 2024 Solutions

In 2023, Siemens released a report that presents ‘The True Cost of Downtime 2022’. According to the report, Fortune Global 500 companies are now losing a staggering 11% of their yearly turnover, or nearly $1.5 trillion, due to unplanned downtime. This figure paints a concerning picture for the plastics industry, where efficient production is paramount. […]

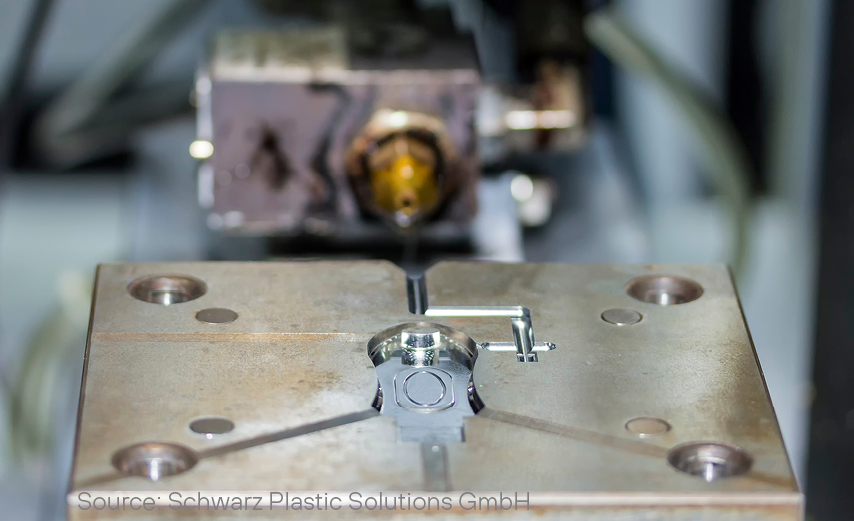

How Our Solution Works: Control Plastics Production Processes

To achieve consistent part quality – regardless of geographical location and seasonal conditions – processors everywhere are seeking out tools that increase stability to more reliably control plastics processes. Given the number of materials and manufacturing processes currently used in this industry, many of the available tools designed to provide molders with more consistent […]

Beyond Black Boxes: Overcoming In-Mold Material Deviations

Plastics manufacturing holds immense potential for innovation and advancement across countless industries. But what happens when the very heart of the production process, the in-mold material behavior, remains hidden behind a ‘black box’? Inconsistent quality, increased scrap rates, and higher energy consumption become costly obstacles, hindering efficiency and profitability. While the desired outcome is a […]

Eliminating Defects: Minimize Scrap to Maximize Yield

Plastics manufacturing thrives on efficiency; each step, from raw material production to final product processing, requires precise control. However, unwanted material loss, commonly referred to as scrap, is a significant challenge that burdens many manufacturers. Defects, inconsistencies, and unforeseen variations can create out-of-spec parts and disrupt production lines, impacting profitability and sustainability. Beyond the immediate […]

Global Plastics Material Trends in 2024

The plastics industry stands as a formidable economic force, with the global market value reaching 712 billion USD in 2023. This industry’s extensive applications in critical sectors such as automotive, aerospace, construction, packaging, and healthcare underscore its integral role in global economic growth and innovation. Among these achievements, the plastics industry is experiencing rapid […]

What Are Thermoplastics: Material Types and Processes

Thermoplastics are integral in various industries due to their versatility, recyclability, and adaptability. From the intricate components within automobiles to life-saving medical devices, thermoplastics are multifaceted polymers. Thermoplastics possess distinctive characteristics, notably the ability to melt and be molded when exposed to heat and revert to a solid state upon cooling. This article outlines what […]

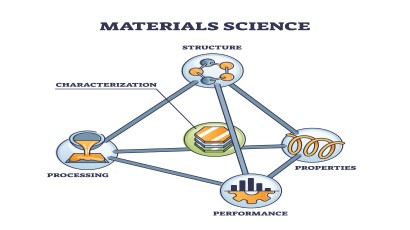

Material Characterization in Plastics Manufacturing

Material characterization is an invaluable factor in plastics manufacturing, encompassing the consistent analysis and evaluation of the properties of polymer materials. Material characterization plays a large role in optimizing production processes, ensuring product quality, and meeting industry standards. This article explores the significance of material characterization in the plastics manufacturing landscape, discusses the various techniques […]

Green Compliance in Plastics Manufacturing: CSRD in 2024

As of 1 January 2024, plastics manufacturers face requirements of transparency, accountability, and sustainable practices as mandated by the CSRD. This article will guide you through the Corporate Sustainability Reporting Directive and its implications for the plastics manufacturing industry. We will present the regulations and key provisions of the CSRD and explore how these changes […]

How to Improve Quality Control in Elastomer Manufacturing

Elastomers are a class of polymers that have unique elastic properties. The term for this polymer stems from its ability to recover to its original form after extensive stretching; specifically stemming from ‘elastic polymer’. Elastomers are ideal for applications in which flexibility and resilience are necessary. The key characteristics of elastomers include flexibility – […]

The Interplay of Economic Efficiency and Energy Savings in Plastics Manufacturing

The two pursuits of economic efficiency and energy conservation are anchors in the plastics industry’s path towards a more sustainable, cost-effective future. Especially amongst a growing demand for streamlined processes and environmentally conscious production practices, plastics manufacturers find themselves divided by a desire to innovate and to carry out responsible production. This article investigates […]

What is Polyurethane? A Materials Case

Polyurethane is an adaptable class of polymers that is used to combat difficulties or challenges in a myriad of industrial and consumer products. The material’s versatility allows it to insulate sensitive components, provide consumer comfort, and resist harsh environmental conditions. Polyurethane can also be molded into numerous sizes and shapes. In this week’s article, […]

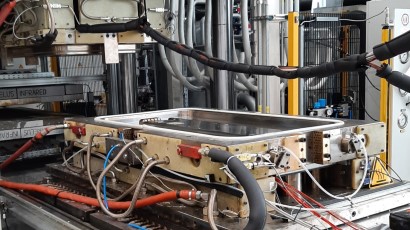

Next-Level Composites Manufacturing: A CosiMo Case

Next-Level Composites Manufacturing: A CosiMo Case With an ever-increasing demand to implement sustainable practices in one’s daily life, such as opting for electric versus gas vehicles, there is also a growing demand for composites manufacturing. In the case of electric vehicles, for example, the car’s total weight influences its driving range. Therefore, engineers are compelled […]

AI and Thermosets: Sustainability in the Plastics Industry

At present, the plastics manufacturing industry faces numerous challenges. One such challenge relates to the changing conditions of production environments and along plastics manufacturing supply chains. Changing conditions, as of late, have been highly attributed to the increasing focus on sustainability and recently introduced legal regulations, such as the Corporate Sustainability Reporting Directive (CSRD) which […]

Feedback Loops, Model Validation, and Retraining: sensXPERT’s Accuracy

sensXPERT Digital Mold is a process control solution that empowers manufacturers to optimize and digitize their plastics manufacturing processes. Predictive machine learning models are central to this technology, as they determine the exact point at which processed materials will have reached a certain degree of cure or crystallization. Therefore, Digital Mold relies heavily on the […]

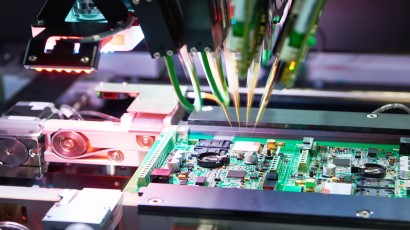

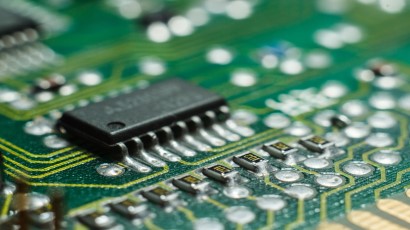

Navigating the Challenges of Electronics Encapsulation

Electronics encapsulation is a pivotal process in the safeguarding of electronic components to ensure their longevity, functionality and their protection from the environment. However, manufacturing encapsulated electronics components can come with a number of challenges, including material variability and electronic vulnerability. Furthermore, striking a balance between quality and cost, while simultaneously addressing location-to-location process inconsistencies, […]

The Essentials of Electronics Encapsulation

In our technology-driven world, there is an ever-increasing reliance on electronics; take smartphones and electric vehicles as examples. However, electronic components can be highly sensitive to various environmental factors, including but not limited to moisture, dust, corrosive chemicals, and physical stress. Fortunately, a technique called encapsulation is applied to sensitive electronic components to shield them […]

Reach for the Sky: How to Optimize Aerospace Composite Manufacturing

In 2022, the estimated market size of the global aerospace plastics industry was $7.14 billion. On top of that, heightening demand for various aerospace structures manufactured out of composite materials is predicted to propel the continued growth of the industry. The increasing demand for the production of aerospace structures can be attributed to growing consumer […]

The Impact of Composites in the Aviation Industry

The aviation industry is ripe-full of advancements and transformation. Materials and processes have evolved ever since the development of the first powered flight by the Wright Brothers in 1915, which was built out of wires, canvas, wood, and steel. The 1920s and 1930s saw a material transition to metals such as aluminum. This was seen […]

Overcoming Automotive Plastics Production Challenges

This article will navigate the various production-specific and industry-wide challenges faced by the automotive plastics manufacturing industry.

EU taxonomy: How SMEs in the plastics industry are affected

How does the EU taxonomy impact SMEs in the plastics industry? Read about the financial effects and new technologies for sustainable production.

Automotive Plastics Manufacturing Trends in 2024

How beneficial is plastic in automotive manufacturing? Read on to learn about the latest automotive plastics manufacturing trends.

Is Plastics Manufacturing Sustainable?

The European Union has outlined its goals for a carbon-neutral society within the next 10 years, yet a major hurdle remains. The production of non-biodegradable materials is growing, and its industries are looking for more ways to tackle the ever-important objective: ‘net-zero’. Plastics: A Growing Industry The first fully synthesized plastic polymer to pioneer global […]

Contactless Measurement of Plastics and Fiber Composites Crosslinking

For about 20 years, the plastics industry has witnessed the coming together of measurement technology and processing. Technical process control challenges, along with a resulting desire for transparency in process technology, brought about initial investments in sensor technology and software tools. This generated certain added value, but desired outcomes often failed to materialize for participating […]

The sensXPERT Digital Cloud Service

In the last two weeks, we introduced three components of our Equipment-as-a-Service sensXPERT Digital Mold solution. Specifically, we covered the sensXPERT material characterization sensors, Edge Device, and WebApp. To round out this series, we will take a closer look at the final element of Digital Mold – the sensXPERT Digital Cloud Service. Developed in collaboration […]

The sensXPERT Edge Device and WebApp

If you have read up on our sensXPERT Digital Mold solution or tried out our illuminating AR Experience, then you might be aware of the vital role played by the sensXPERT Edge Device in collecting and transferring process data. You might have also learned about on the WebApp, an interface to the Edge Device which […]

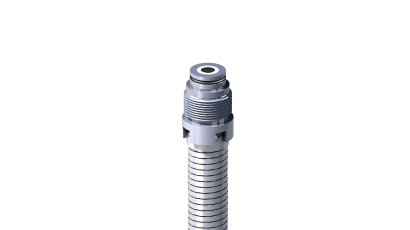

sensXPERT Material Characterization Sensors

Material characterization is invaluable in plastics manufacturing. Through the implementation of material characterization tests, manufacturers can ensure the quality, performance, and safety of their final products. There are numerous material characterization techniques and tests that can be conducted at different stages of production. This article will examine in-mold material characterization in specific. Additionally, we will […]

5 Ways to Optimize your Thermoset Production for Industry 4.0

With more industries advancing with the rapid trend of digitization, thermosetting has become a key manufacturing focus for its ever-growing demand. The question stands: how can thermoset production be optimized to maintain supply and demand from some of the globe’s largest sectors? Thermoset Production in 2023 The world of manufacturing has changed dramatically over the […]

Exploring the Plastic Industry’s Materials Landscape

To be well-informed in plastics manufacturing environments, considerable understanding of the materials involved is paramount. Found in daily consumer products and components used in significant industries such as automotive, aviation, and electronics, plastic use is widespread. So, what makes plastic so versatile and functional? The answer can be found in the careful selection and application […]

Accelerating Quality Control in Plastics Manufacturing

In the efficiency-driven world of plastic part manufacturing, yielding products of the highest quality is integral to customer satisfaction, product reliability, and securing a competitive edge. Implementing quality control (QC) measures is one way for manufacturers to guarantee final part quality. However, there are several factors that might impede the ability to successfully conduct quality […]

The Problem with Plastic: #3 Quality Assurance

Quality assurance is paramount in the plastics manufacturing industry. If a manufacturer’s plastic part production proved unreliable and substandard, customers would be left unsatisfied, manufacturers would not meet industry standards, and they would be unable to compete effectively in such a demanding industry. To wrap up our series on ‘The Problem with Plastic,’ our final […]

The Problem with Plastic: #2 Process Stability

Process stability is essential in plastic part manufacturing. By maintaining a stable process, challenges such as manufacturing defects are less likely to occur. However, it is not always easy to foresee deviations or issues that would otherwise require immediate process adaptation. Last week we looked at various types of manufacturing defects and how to deal […]

The Problem with Plastic: #1 Manufacturing Defects

Manufacturing defects, fluctuations in part quality, and the manufacturing ‘black box’ are a few pain points that plastic part producers face in their day to day. Not only do these challenges limit productivity, but they can also be costly and energy inefficient. To help plastic manufacturers combat these difficulties, our new blog series ‘The Problem […]

Presenting: The sensXPERT Way of AI

Now, in our final article on the sensXPERT way of AI, we would like to bring you along as we take a closer look at our technology and use of AI to address challenges in the plastics manufacturing industry.

Data Science: The sensXPERT Way of AI

In a world of ever-growing technological advancements, data science, artificial intelligence (AI), and machine learning (ML) have become commonplace yet intermingled terms. In part two of our series on the sensXPERT way of AI, we will explore data science as a significant collaborator of AI and ML. In part one of our series, we looked […]

Artificial Intelligence and Machine Learning: The sensXPERT Way of AI

The plastics industry is one of the many industries currently being transformed by artificial intelligence (AI). Inspired by human cognitive behavior, this revolutionary technology enables machines to perform tasks such as recognizing speech, images, and patterns. The potential applications of modern AI and machine learning (ML) are expansive. Still, in the plastics industry, their use […]

Trenchless sewer rehabilitation with UV

Material, technology, and latest innovations for reliable quality control and safety improvement ProKASRO Mechatronik and NETZSCH Process Intelligence jointly release game-changing information on the latest technology, enabling the UV liner’s curing mechanism to increase performance. The NO-DIG movement is widely spread, and trenchless sewer rehabilitation is a means to an end. The promising novel method […]

Demystifying sensXPERT

We have a lot to unpack. We have told you a lot so far, but now we want to share how sensXPERT technology really works. Hence, we are now on a mission: Demystifying sensXPERT. We’d like to get straight to the point by clearing up a misunderstanding. sensXPERT is our brand. Our company name is […]

Process optimization thermosets: How to solve the challenges of the future

Political demands for more sustainable manufacturing processes are a major challenge. In addition to the associated risks, there are great opportunities for companies that are open to these changes.In the world of thermosets, process optimization is key to meeting these challenges. In this article, you will learn how you as a thermoset processor, but also […]

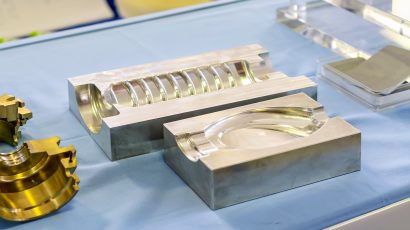

Mold Better Parts Faster at Lower Cost: It’s Possible with Real-Time In-Mold Access to Material Characterization Data

In order to produce quality thermoset parts quickly and consistently, processors need real-time access to four pieces of data at any given point in each molding cycle: These four important sets of material characterization data are available in real time from sensXPERT’s in-mold dielectric monitoring system. Gel Point Knowing how close you are to the […]

5 Key Takeaways: Solving Challenges in Processing Thermosets in Real-Time

The plastics industry has seen significant changes in the last years – both at the macro and micro level. We have closely looked at current industry trends in two webinars and shed light on the challenges of processing thermosetting materials. Utilizing the multi-faceted opportunities that digitization and collaboration have to offer allows the transformation of […]

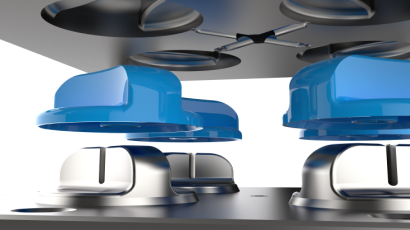

Innovative sensors creating intelligent molds

Excerpt Polymer processing with thermosets is the key to high-performance parts regarding mechanical strength and durability. However, the material causes many challenges in production. In a customer-centric approach, the new sensXPERT solution provides a state-of-the-art solution to tackle lacking transparency and high scrap rates. sensXPERT delivers a unique solution for processors in the polymer and […]