The Problem with Plastic: #2 Process Stability

Process stability is essential in plastic part manufacturing. By maintaining a stable process, challenges such as manufacturing defects are less likely to occur. However, it is not always easy to foresee deviations or issues that would otherwise require immediate process adaptation.

Last week we looked at various types of manufacturing defects and how to deal with them. We also discussed the benefit of process transparency and how in-process visibility can help manufacturers adapt their processes and avoid defective parts.

In our second article on “The Problem with Plastic”, we highlight several common processes in plastic part production, the issue with unstable processes, and how to achieve process stability.

5 Plastics Manufacturing Processes

Before delving into the challenges manufacturers face with process stability, the following five processes can help give a clearer picture of production types in plastics manufacturing. These processes wield thermosetting, thermoplastic, and/or rubber materials to produce plastic parts.

Compression Molding:

Compression molding is a simple manufacturing process used for thermoset, thermoplastic, and rubber part production. Before loading raw material into a mold, the mold is preheated to a specific temperature. The raw material is then deposited into the mold cavity. After closing the mold, a hydraulic or mechanical press subjects the mold to high pressure to ensure that the material is evenly distributed throughout the mold – a.k.a. compression. Both heat and pressure are then applied to the mold, which softens the material and allows it to fill the entire cavity. The molding cycle continues for a predetermined period to ensure sufficient curing. Eventually, the mold is cooled, and the final part is ejected.

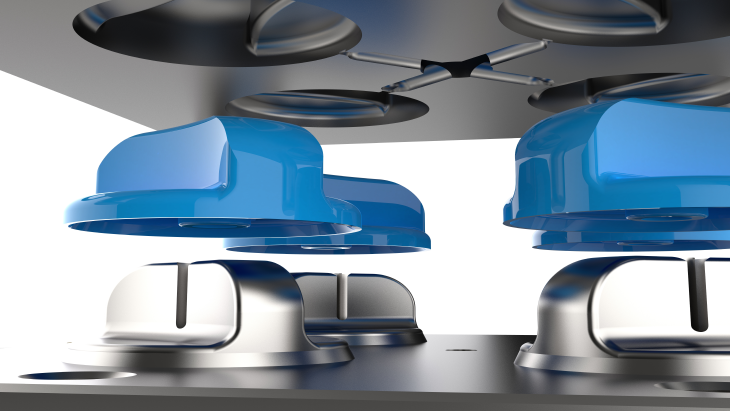

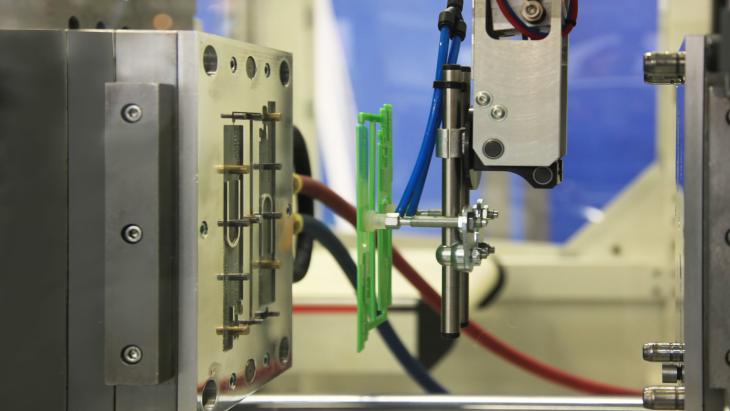

Injection Molding:

One of the most widely used part production processes, injection molding can be used to manufacture thermoset, thermoplastic, and rubber parts. The desired material, in pellet, granule, pasty, or liquid form, is heated until melted, or softened in the machine’s barrel. Under high pressure, the material is injected into a mold cavity through a nozzle at a specific injection speed. In the case of thermoplastics, after filling the mold, the material cools and solidifies according to the shape of the mold. Lastly, the final part is ejected.

Reaction Injection Molding

A specific type of injection molding, reaction injection molding is used to produce rubber and thermoset parts. In this process, two or more liquid substances are mixed. This mixture is then injected into a mold at moderately low temperatures in order to avoid premature material curing. In the mold, the material mixture is heated and forms chemical crosslinks. This chemical reaction leads to the curing and solidification of the material. Finally, the mold is opened, and the completed part is ejected.

Figure 1: Injection Molding

Transfer Molding:

Transfer molding is a process that can be used to produce plastic and rubber parts, specifically those with more complex geometries. A combination of elements from compression molding and injection molding is applied in this process. Initially, the mold is preheated to a designated temperature. The raw material is preheated in a pot equipped with a plunger or transfer piston at the bottom. Once the material is viscous, it is forced into the mold while hydraulic pressure is applied to the plunger or transfer piston. The mold is then subject to certain heat and pressure profiles for a specific amount of time. Once the material cures, solidifies, and cools, the final part is removed from the mold.

Thermoforming:

Thermoforming is a process that takes thermoplastic sheets and shapes them into various forms and sizes. To start, a thermoplastic sheet is heated to a temperature above its glass transition temperature or melting point. In doing so, the sheet will soften, become pliable, and be easy to shape. Once it has reached the desired temperature, the sheet is placed over a mold and is subject to vacuum or pressure so that it conforms to the mold. The sheet then cools, solidifies, is removed from the mold, and trimmed to remove any flash or excess material.

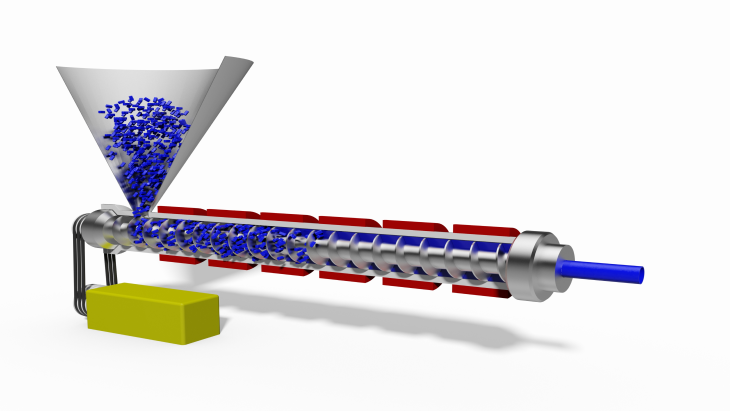

Extrusion:

Extrusion is a process that yields continuous thermoplastic and rubber profiles. The raw materials are fed into the machine, otherwise called an extruder. In the extruder, the material is heated and mixed. The material then moves through and exits a die that turns it into a desired profile or shape. For the material to solidify in its established shape, thermoplastic parts undergo a cooling process and rubber parts undergo a heating process. Lastly, the resulting material can either be cut into various lengths or rolled up into spools.

Figure 2: Extrusion

Process Stability

Now that we’ve introduced a few different manufacturing processes, we would like to tackle the challenge of process instability that might befall any one of these processes.

A lack of consistency, predictability, and visibility is indicative of an unstable process. Processes that are susceptible to deviations or are not entirely under control often result in final part defects and scrap production. There are many reasons as to why a process might become unstable, and, with limited visibility during production, it can be very difficult to immediately detect an unstable process.

What Causes Process Instability?

Material Behavior:

Conditions ranging from temperature, humidity, storage, and aging can all play a role in material behavior during processing and compromise process stability. In the case of temperature, high temperature exposure can impact material properties, such as viscosity, melt flow, mechanical strength, or can even lead to material degradation. On the other hand, if a material is exposed to exceedingly low temperatures, it could turn brittle. Additionally, certain materials can absorb moisture from their environment, which can subsequently affect their behavior during processing and result in final part defects, such as voids and bubbles. Batch-to-batch variations because of process instabilities in material manufacturing might also impact behavior during part production.

Process Parameters:

Process parameters such as temperature, pressure, cooling time, and more can negatively impact process stability if improperly set or if they deviate from predetermined reference settings.

Mold Issues:

Mold issues such as damage, inadequate venting, and irregular alignment can destabilize processes and lead to part defects.

Lack of Process Monitoring:

Possibly one of the more significant constraints in maintaining process stability is having a lack of process monitoring. Generally, processors are inconvenienced by the manufacturing ‘black box’, which refers to the limited visibility on what occurs within a mold, how a material is behaving, if process parameters are correct, and if a mold has issues or not.

Overall, unstable processes can lead to scrap part production, reduced productivity, high energy usage, high costs, and general inefficiency. So, how can this be dealt with?

Dealing with Unstable Processes

With a lack of process monitoring being one cause of process instability, implementing process monitoring systems can help combat the issue. To achieve process stability, full transparency during production supports manufacturers in tracking and adjusting their processes in real-time. In other words, the ability to dynamically adapt processes aids manufacturers in avoiding process deviations and final part defects. Rather than solely relying on assumptions based on laboratory simulations, process monitoring equips manufacturers with reliable real-time data.

sensXPERT offers an in-mold process monitoring system that can do exactly that. The predictive analytical tool provides manufacturers with transparency, real-time in-mold data, and the possibility of adaptive process control. A few advantages of adapting cycles and maintaining process stability include cycle time reduction, less scrap production, heightened productivity, energy efficiency, and more. You can read more about sensXPERT Insight here.

In this article we covered issues with process stability in plastic part manufacturing, highlighted a few commonly used processes, and discussed process monitoring as a practical solution. Our final article on ‘The Problem with Plastic’ will tackle quality assurance challenges in plastics manufacturing.