The Problem with Plastic: #3 Quality Assurance

Quality assurance is paramount in the plastics manufacturing industry. If a manufacturer’s plastic part production proved unreliable and substandard, customers would be left unsatisfied, manufacturers would not meet industry standards, and they would be unable to compete effectively in such a demanding industry.

To wrap up our series on ‘The Problem with Plastic,’ our final article will uncover the industry’s various challenges in quality assurance, touching upon the previous topics of manufacturing defects and process stability.

Achieving consistent quality in plastics manufacturing can be filled with difficulties, from defect detection and environmental influences to process stability and quality assurance inspections. This article will highlight four common challenges associated with quality assurance and a valuable solution to overcome them.

What is Quality Assurance?

Quality assurance (QA) encompasses the processes, practices, and activities implemented in a manufacturing environment to guarantee production that meets quality standards. Throughout a production cycle, everything from design and raw material selection to manufacturing processes, inspections, and product distribution falls under the umbrella of QA.

Why is QA important?

Quality assurance in manufacturing is pivotal for many reasons. QA ensures product reliability, such that products meet performance requirements. QA also maintains customer satisfaction by seeing to it that customers receive high-quality products according to their expectations. Manufacturers implement QA to comply with standards, regulations, and safety; achieve certifications; and enforce legal obligations. Additionally, by effecting QA measures, raw material deviations can be identified, and product defects can be minimized, thus reducing scrap production and costs.

QA fosters efficient production, customer satisfaction, and profitable manufacturing operations.

Quality Assurance versus Quality Control

While quality assurance refers to the processes and measures involved in managing quality in manufacturing, quality control is a subcategory of QA that refers to the monitoring and inspection of production processes. Quality control includes inspecting products for defects or issues that might impact performance, safety, etc.

Besides quality control, a couple of other steps are important to QA: quality planning and quality improvement. Quality planning is the initial step when manufacturers lay out quality objectives and determine the necessary processes to accomplish them. Quality control falls between quality planning and quality improvement. The latter is a final step during which manufacturers locate areas of development and introduce measures to improve qualitative production further.

| Quality Assurance | Quality Control |

|---|---|

| Focuses on processes and measures of quality management in manufacturing. | A subcategory of quality assurance that focuses on monitoring and inspecting manufacturing processes. |

| Includes three key steps: quality planning, quality control, and quality improvement. | Involves inspecting products for defects or issues that could impact performance or safety. |

| Quality planning establishes quality goals and defines the processes required to achieve them. | Falls between quality planning and quality improvement, ensuring established standards are met. |

| Quality improvement identifies opportunities for enhancing manufacturing quality. | Helps detect potential defects early and implement corrective actions. |

Table: Comparison of Quality Assurance and Quality Control – Differences in Processes, Focus Areas, and Their Role in Manufacturing.

Four Common Challenges in Quality Assurance

QA is consequential in manufacturing, specifically plastic part manufacturing. However, plastic part production is complex and challenging. The following four points are common challenges plastics manufacturers face concerning quality assurance.

| Challenge | Description |

|---|---|

| Defect Detection & Analysis | Visual inspections can be challenging, especially for complex geometries. Subtle defects may be overlooked despite experienced inspectors and clear inspection criteria. |

| Process Stability & Deviations | Fluctuations in raw materials or between batches can impact quality. Material behavior is influenced by factors such as temperature, humidity, and storage conditions. |

| Environmental Influences | Temperature, humidity, and dust levels vary by region and can affect material flow, cooling, and curing, leading to defective parts. |

| Quality Assurance Inspections | Quality assurance inspections take place before and after processing to assess raw material and final part quality. Insufficient control can result in quality issues. |

Here is a more detailed examination:

- Defect Detection & Analysis

Visual inspections that are carried out to detect defects or analyze part quality can prove to be difficult. Complex parts with intricate geometries require more meticulous checks, and inspectors might miss subtle defects. Even with skilled inspectors, adequate lighting, and clear-cut inspection criteria, defects can be overlooked.

- Process Stability & Deviations

Batch-to-batch deviations or variations in raw materials can negatively impact the final part quality. Generally, raw materials will not behave consistently during processing, even if the materials stem from the same supplier. Many factors, including temperature, humidity, and storage conditions, influence material behavior.

Additionally, monitoring processes in real-time can be difficult without adequate material and machine behavior transparency. Therefore, prompt reactions to process deviations are difficult to implement and can lead to quality reductions.

Discover how to successfully manage material deviations in plastics processing with this free English-language whitepaper – instant access, no form required.

- Environmental Influences

As the previous challenge mentioned, environmental influences like temperature and humidity affect material behavior. Additionally, changes in these factors can impact material flow, part cooling, or curing, which may lead to defective parts. Assuring quality under varying environmental influences is tricky, especially in regions with extreme climates. For example, some regions may be more prone to high temperatures, some to extremely low temperatures, humidity may vary in different regions, and some regions might experience more dust.

Accordingly, some production environments also make it challenging to control contamination. Dust, oil, or foreign particles can become embedded in a material during processing, leading to poor part quality.

- Quality Assurance Inspections

The final quality assurance challenge is QA inspections. QA inspections can occur before processing to assess raw materials and post-processing to determine part performance and quality. In many cases, these inspections can be unreliable. Quality sampling is a technique in QA inspections in which a sample of a material or product batch is tested to determine the state of the entire batch. This technique has limitations because an unsuitable material or defective part could be left undetected. Additionally, it is highly cost intensive due to the number of human resources needed to carry it out.

Innovative Technological Solution

The outlined challenges can lead to several disadvantages, such as needlessly high scrap rates, costs, and energy waste. Fortunately, technological solutions to combat quality assurance problems are on the rise. More distinctively, technologies that wield predictive algorithms and have process monitoring capabilities can aid in performing quality control during production.

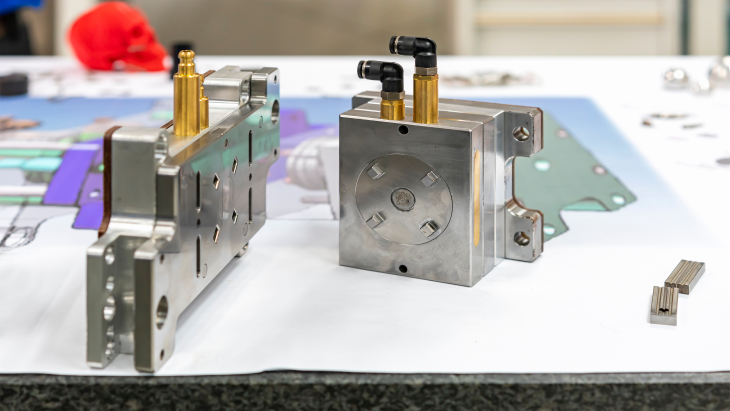

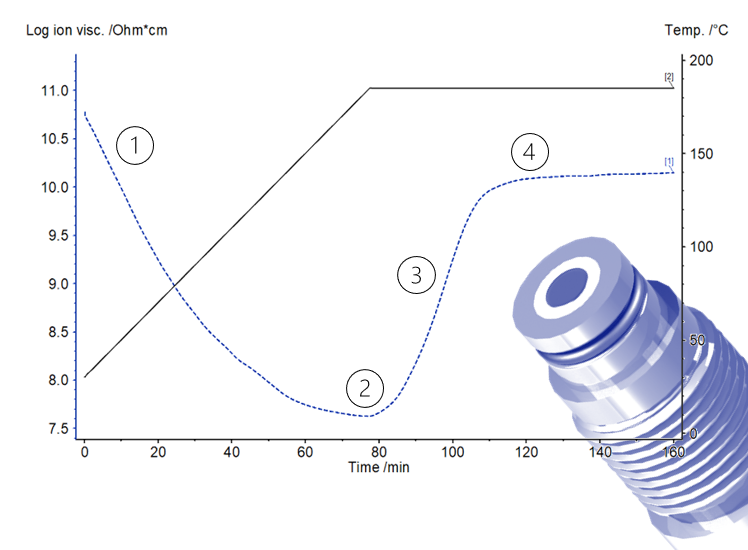

The sensXPERT process monitoring solution, Digital Mold, is an innovative tool with which manufacturers gain transparency in their processes. Digital Mold uses material characterization sensors that map out material behavior and environmental influences within a mold in real-time.

Furthermore, manufacturers can profit from this technology and adapt their processes dynamically should production parameters deviate. The forecasting capabilities on sensXPERT Digital Mold alert manufacturers if specific quality criteria will not be met in each cycle.

Manufacturing defects, process stability, and quality assurance can pose challenges but are ultimately intertwined. With the conclusion of ‘The Problem with Plastic’ series, the solution is more evident than ever; technologies with process monitoring abilities – such as sensXPERT – enable manufacturers to adjust their processes in real-time. Thus, defects can be avoided, process stability can be maintained, and quality assurance measures are strengthened.

Webinar: Automated Quality Control in Composite Manufacturing with Dielectric Sensors

Learn how automated quality control in composite manufacturing reduces scrap and increases productivity. In this English-language webinar, you will discover how manufacturers handle material deviations and production anomalies, utilize dielectric sensors in various processes, and leverage Digital Mold technology for process optimization. Explore real-world case studies and see how innovative sensor technology enhances quality and reliability in manufacturing.