The Essentials of Electronics Encapsulation

In our technology-driven world, there is an ever-increasing reliance on electronics; take smartphones and electric vehicles as examples. However, electronic components can be highly sensitive to various environmental factors, including but not limited to moisture, dust, corrosive chemicals, and physical stress.

Fortunately, a technique called encapsulation is applied to sensitive electronic components to shield them from these environmental challenges. Electronic encapsulation transforms vulnerable electronics into robust, resilient devices.

In this article, we will expand upon the definition of electronics encapsulation, relay the importance of encapsulating electronic components, and outline common processes and plastics materials used for encapsulation.

What is Electronics Encapsulation?

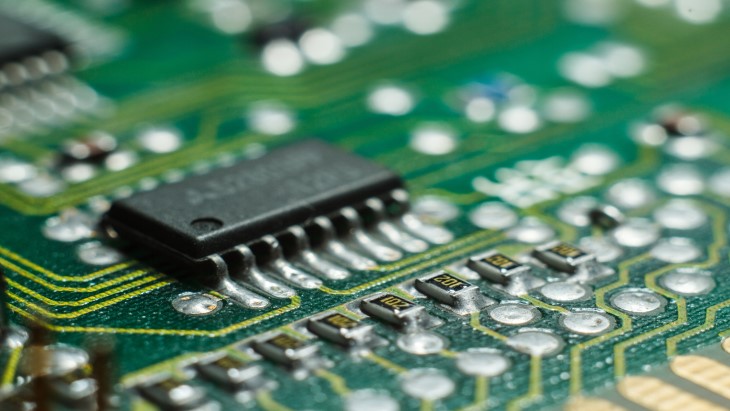

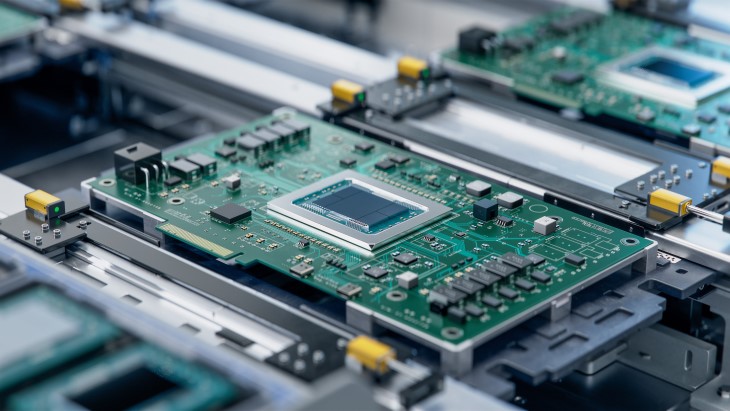

Electronics encapsulation is the process of creating a secure ‘casing’ or ‘coating’ over sensitive components to ensure their durability in the face of shock, corrosive chemicals, vibrations, and more. The materials constituting this protective layer are selected based on the electronic components’ specific applications, but typical material choices include epoxy resins, polyurethanes, and silicone rubber.

Not to be confused with potting, which is the placement of a part in a container to partially or completely embed it with resinous material, encapsulation is a process that wields a reusable mold to coat components with the material.

Encapsulation is a crucial step in the manufacturing of electronic devices, as it ascertains the devices’ effective operation under difficult conditions and long-term functionality. It is also a process that works in conjunction with other safeguarding measures like conformal coating and sealing and bonding.

Why Encapsulate Electronic Components?

The encapsulation of electronic components serves various purposes, including protection against environmental influences, electrical insulation, and enhanced security. It helps ensure the longevity and reliability of electronic systems and is indispensable in many industries, including aerospace, automotive, and medical technology. The following table provides an overview of the key reasons for encapsulating electronic components.

| Aspect | Description |

|---|---|

| Environmental Protection | Sensitive electronic components are encapsulated to protect and insulate them against environmental conditions such as moisture, contamination, vibration, physical shock, harsh chemicals, and more. |

| Electrical Insulation | All materials used to encapsulate electronics must be electrically insulating, which prevents unintended electrical contact between different components and reduces the risk of short circuits. |

| Thermal Management | Some encapsulation materials have properties that aid in thermal management by dissipating heat generated by electronic components. |

| Security and Tamper Resistance | Encapsulation can be used to enhance the security of electronic devices by making it more challenging for unauthorized individuals to access or tamper with sensitive components. |

| Longevity and Reliability | Components that are encapsulated generally experience a longer service life than those that are not, making them more reliable for critical applications in which downtime or failure is unacceptable. Examples of such applications include the aerospace, automotive, and medical industries. |

| Compliance with Industry Standards | The abovementioned industries also have very specific and rigorous standards and regulations that must be abided by, which will often include the reliable encapsulation of electronics. |

Table: Overview of key reasons for electronics encapsulation, including protection, insulation, thermal management, security, reliability, and compliance with industry standards.

Overall, encapsulating electronics is a significant process that not only protects electronic components from environmental factors but also enhances their durability, reliability, and performance. It is a necessary approach to maintaining the effective operation of electronic devices in a wide range of applications and conditions.

Prevalent Materials Used in Electronic Encapsulation

Formerly, electronic components were protected by materials such as metals, ceramics, and glass. These materials were eventually substituted with polymers, and the most preferred material choices for encapsulation today are epoxy resins, silicones, and polyurethanes. These three materials have varying significant characteristics that make them suitable for different encapsulation applications.

Silicones have good heat resistance and can withstand temperatures from about -50°C to 200°C. Silicones are also self-extinguishing, making them the appropriate choice for applications requiring flame retardancy. Silicones are moisture and UV resistant, which in combination with the previously mentioned characteristics, makes the material ideal for harsh environments. Furthermore, silicones have good vibration resistance, which is useful for applications like turbines or engine housings.

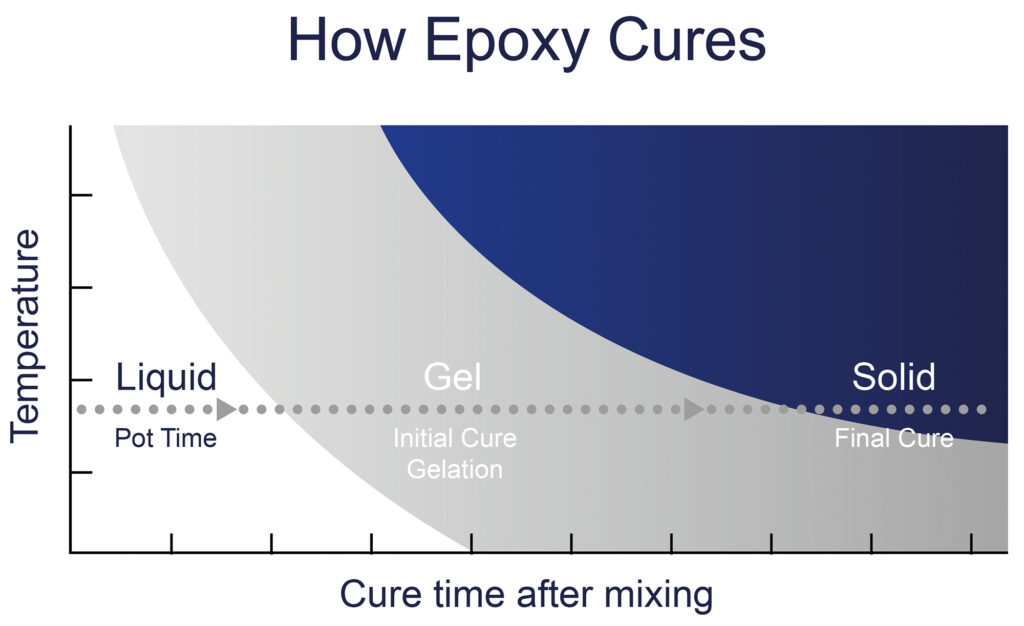

Epoxy resins present exceptional dielectric properties – thermal conductivity being one – as well as moisture and chemical resistance. Epoxy resins can also withstand temperatures from around -50°C to 200°C. This material offers high adhesion and mechanical strength, and they are generally suited to high-voltage applications.

In comparison to epoxy resins, which become hard and rigid when cured, polyurethanes typically become slightly more flexible than the average epoxy, but polyurethane properties can be extremely widespread. This is especially practical when dealing with delicate components. Similar to epoxy resins, this material is also chemical and moisture resistant and provides great electrical insulation. However, when comparing polyurethanes to silicones and epoxy resins, polyurethanes can withstand a smaller temperature range of about -40 °C to 150°C.

Three Encapsulation Processes and How They Work

In this section, we will be exploring a few common closed mold processes used to encapsulate electronics in manufacturing environments.

Injection Molding

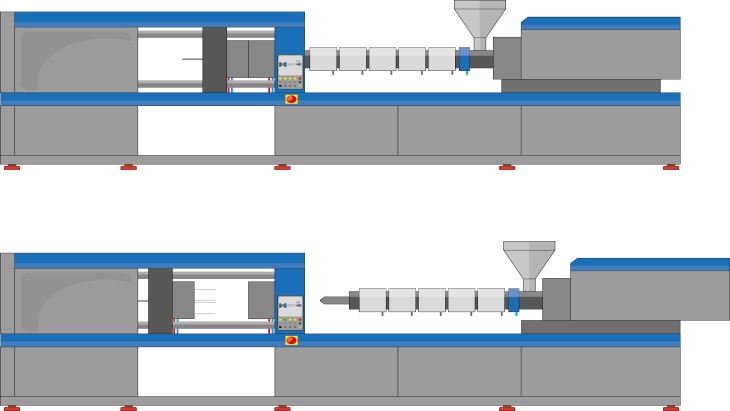

Injection molding is one of the most widely used manufacturing processes for the production of plastic parts and products. It is an efficient, cost-effective process for the mass-production of components with complex shapes and precise dimensions.

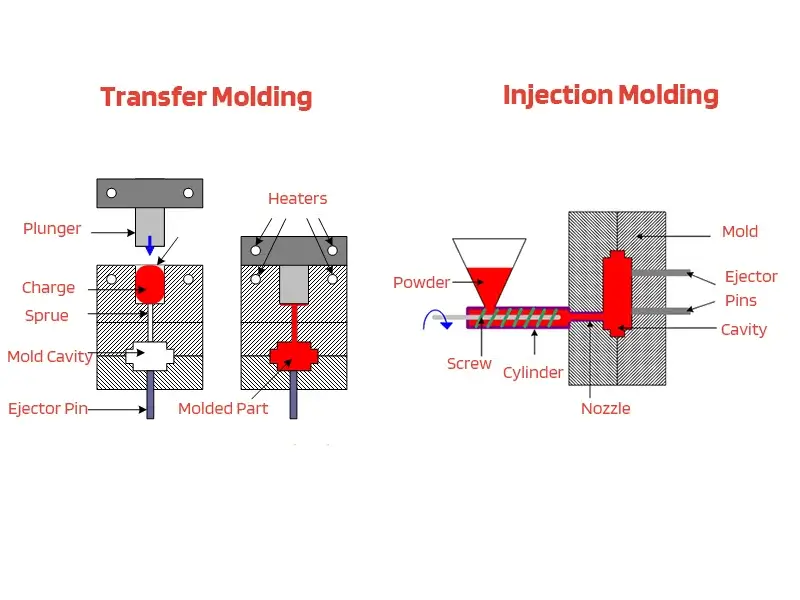

The mold in an injection molding machine is typically composed of steel or aluminum and consists of two halves; a core and a cavity. These two halves are designed to match the intended shape of the final product.

The process begins by feeding raw plastic materials, in the form of pellets or granules, into a heated barrel. The material moves through a screw and is then injected into the mold cavity and held under pressure for a period of time. Finally, the part is cooled and ejected from the machine.

Over Molding

Over molding is a molding process used to mold one or more components over another component. In this process, a pre-formed part or, in the case of electronics encapsulation, an electronic component is placed within the mold and the heated raw material is injected into the mold to form a protective layer around the electronic component.

Transfer Molding

Another process that can be used to encapsulate electronics is transfer molding. This process is relatively similar to injection molding but differs in that the transfer molding machine includes a plunger and transfer pot – instead of an injector screw – to force the raw material into the mold cavity.

To encapsulate electronics, transfer molding is carried out by placing the component that will be encapsulated into the mold cavity. Resin is forced into the mold cavity and encapsulates the component already held within the mold.

In our next article we will navigate the challenges of electronics encapsulation, including material variability, electronic vulnerability, high material costs, and location-to-location inconsistencies, and provide insight on a technology-based solution that addresses these challenges.

In the meantime, if you want to learn more about optimizing electronics encapsulation processes, watch our on-demand webinar about ‘Process Optimization of Electronics Encapsulation with Reactive Thermosets’.