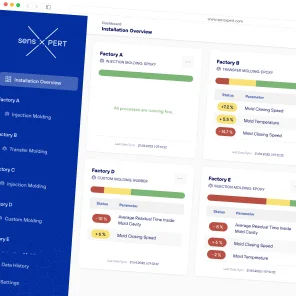

Powerful Plastic Molding Technology: The Complete sensXPERT Solution

Features Built for industry 4.0

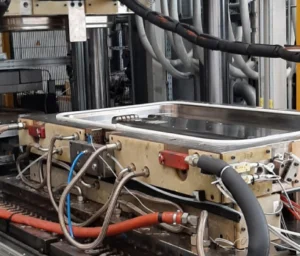

Plastics manufacturing processes that can benefit from sensXPERT

Materials Supported by sensXPERT

With thermosets, sensXPERT focuses on chemical reactions – the so-called “curing”- and material changes during molding. The versatility of dielectric signals recorded by sensXPERT’s sensors, which are in direct material contact during molding, allows sensXPERT to capture in-process material behavior. This includes mixing ratio effects and the effects on curing, which conventional DSC (Differential Scanning Calorimetry) or DMA (Dynamic Mechanical Analysis) techniques cannot capture. sensXPERT is experienced in successfully working with a wide range of thermosets, from epoxies, polyurethanes, phenolics to unsaturated polyesters.

Challenges when using thermosets:

The manufacturing of thermoset composites presents several challenges due to factors such as the utilization of novel resin formulations and the chemical reactions involved in combining reinforcements and fillers. Additionally, there is a need for faster reactions and shorter cycle times, and the process must accommodate environmental variations whilst meeting the unique specifications of the component being produced.

How sensXPERT solves this challenge:

sensXPERT’s plastic molding technology follows the chemical reaction of the material during molding to link design, manufacturing, digitalization, and quality control.

Relevant industries:

-

Automotive & e-mobility: semiconductor encapsulation, e-motor components, gear housing, electric power trains, lightweight structural components, and applications requiring low vibrations, low noise and improved heat dissipation.

-

Aerospace & Defense: composite fuselage sections, frame structural reinforcements, and rear fuselage.

-

Electrical, building, and construction: construction equipment panels, heat shields, electric enclosures, load breakers, disk breakers, along with pipes and sewer rehabilitation using UV light liners.

-

Renewable energy: wind turbine structural components, heat shields or encapsulation, frames for silicon panels, roof tiles and electrical enclosures used for solar energy.

In terms of thermoplastics, sensXPERT focuses on detecting phase changes during melting and crystallization, as well as the glass transition temperature and other relevant parameters.

Challenges when using thermoplastics:

Manufacturing that uses thermoplastics is confronted with numerous obstacles, such as stiff competition and cost reduction pressures. The integration of new blends and compound formulations, alongside the inclusion of pre- and post-consumer recycled materials, each with their intricate thermal histories and compositions, presents additional difficulties. Furthermore, environmental factors exert a considerable influence, and the material’s behavior inside the mold is not yet fully comprehended.

How sensXPERT solves this challenge:

sensXPERT aims to track the thermoplastic material throughout the molding process by integrating processing, material science, and digitalization to minimize manufacturing scrap and quality control complications. Particularly with sensXPERT’s material characterization sensors, various manufacturing processes such as injection molding and its variants, primary recycling, extrusion, blending, primary and secondary recycling, and compounding can all reap significant benefits. We are currently focusing on the technical applications of polyamides and their variations, such as aramids, nylon, and Kevlar and primary and secondary recycling with polyethylene (PE) and polypropylene (PP) and support molders. The challenge here is to ensure a stable manufacturing process.

Relevant industries:

-

Automotive & e-mobility: transmission parts, fuel tanks, lubricant tanks, and parts that provide insulation, periodic fatigue resistance and wear resistance.

-

Electrical, building, and construction: electrical tool housings, escalator handrails

-

Primary recycling: extrusion of pre-consumer or pure polymer streams.

-

Secondary recycling:sorting polymer waste streams, reducing the size of the polymer waste, and then extruding the material.

Similar to thermosets, sensXPERT’s plastic molding technology concentrates on chemical reactions – the so-called “vulcanization” – and material alterations during elastomer processing. The adaptability of dielectric signals recorded by sensXPERT sensors, which are in direct contact with the material during molding, enables sensXPERT to record the material’s behavior during processing. This includes the impact of mixing ratios and vulcanization, which conventional DSC (Differential Scanning Calorimetry) or DMA (Dynamic Mechanical Analysis) techniques cannot detect. sensXPERT has extensive experience with nitrile rubber (NBR), hydrogenated nitrile butadiene (HNBR), ethylene propylene diene terpolymer (EPDM), fluoroelastomer (FKM) and liquid silicone rubber (LSR).

Challenges when using elastomers:

The production of elastomer products entails numerous obstacles. Firstly, there’s the complex nature of the chemical reaction to consider, particularly when it is combined with a high filler content. Another potential challenge is the uneven mixing process used to produce pre-vulcanized elastomers. Finally, it is also worth mentioning the effects of unforeseen processing and environmental fluctuations on the finished product’s required specifications.

How sensXPERT solves this challenge:

sensXPERT helps manufacturers optimize their reaction injection molding (RIM) and extrusion processes, including variations of these specific manufacturing processes. It is important to remember that our portfolio continues to expand, especially as we strive to follow the chemical reaction of the component during molding, linking design, manufacturing, digitalization, and quality control.

Relevant industries:

-

Automotive & e-mobility:seals, gaskets, o-rings, pipes, hoses, vibration damping applications, and bushings.

-

Electrical, building, and construction: load breakers, cords, tubing, power transformers, and parts that provide electrical and thermal insulation/damping.

sensXPERT’s plastic processing solution concentrates on chemical reactions and material alterations during composite production. The variability in dielectric signals recorded by sensXPERT sensors, which are in direct material contact during molding, allows sensXPERT to capture in-process material behavior. This includes mixing ratio effects and the effects on curing, which conventional DSC (Differential Scanning Calorimetry) or DMA (Dynamic Mechanical Analysis) techniques cannot capture. sensXPERT is experienced in successfully working with a wide range of composites including carbon fibre-reinforced polymers (CFRP) and glass fibre-reinforced polymers (GFRP).

Challenges when using composites:

Composite materials are often used in high-performance applications and are, accordingly, required to withstand extreme temperatures, pressures, and stress. Additionally, the manufacturing of composites presents several challenges due to factors such as the utilization of novel resin formulations and the chemical reactions involved in combining reinforcements and fillers. Additionally, there is a need for shorter cycle times, improved product quality, and the process must accommodate environmental variations whilst meeting the unique specifications of the component being produced.

How sensXPERT solves these challenges:

sensXPERT’s plastic molding technology follows the chemical reaction of the material during molding to link design, manufacturing, digitalization, and quality control.

Relevant industries:

-

Automotive & e-mobility: lightweight structural components, and applications requiring low vibrations, low noise and improved heat dissipation.

-

Aerospace & Defense: composite fuselage sections, frame structural reinforcements, and rear fuselage.

-

Renewable energy: wind turbine structural components.

Material benefits

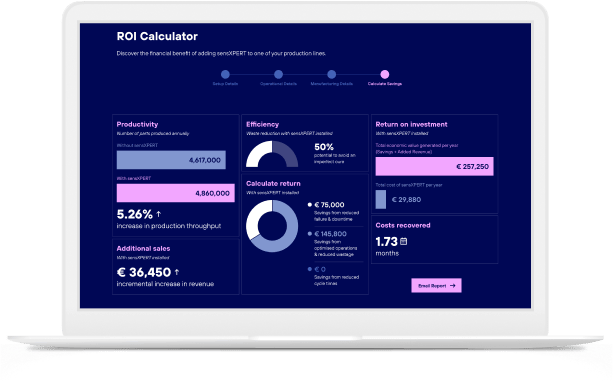

ROI Calculator

Calculate the real value of sensXPERT for your manufacturing business

Considering sensXPERT for your business? Use our powerful ROI calculator and see how much of a return this could make for your business.

Launch ROI calculator