How to Achieve Process Control in Plastics Manufacturing

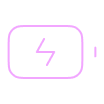

The power of sensXPERT lies in its direct connection to your shop floor machinery. At the forefront is the sensXPERT material characterization sensor, which uses dielectric analysis and maintains direct contact with the raw material inside the mold, continuously collecting real-time data about the material's behavior.

At the same time, the sensXPERT Edge Device takes this wealth of data and integrates it with pre-existing kinetic models, generating advanced predictive machine learning models.

These machine learning models are instrumental in forecasting properties like the degree of cure or crystallization, glass transition temperature, and other relevant thermal or mechanical attributes of the raw material in processing. If these predictions stray from the target value, the process can be dynamically fine-tuned until the predictions align with the desired value. This adaptability, fueled by real-time data and predictive insights, helps produce a higher quantity of quality parts while reducing waste.

Ultimately, this system boosts your ability to detect quality changes, control your processes, and optimize your plastics manufacturing in a truly dynamic and adaptable way.

Relevant industry challenges

To understand the true potential of a feature such as real-time process optimization, it is important to revisit the various industry challenges it addresses. Below are several challenges or pain points that you may recognize:

Benefits of real-time process optimization

Explore real-world success stories with sensXPERT

Improving in-mold transparency in the electrical encapsulation industry

Find out how two companies successfully used sensXPERT on their reaction injection molding processes to boost in-mold transparency and reduce scrap production rates.

Find out more