A whole new raft of manufacturing capabilities

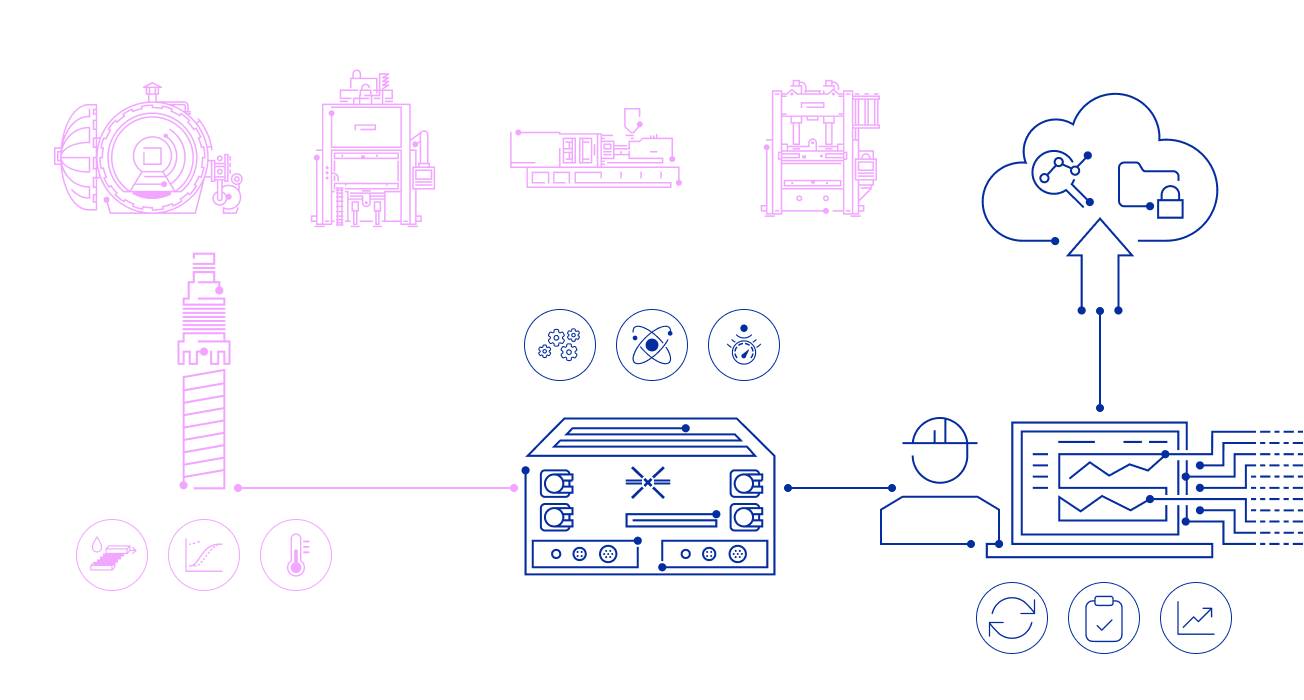

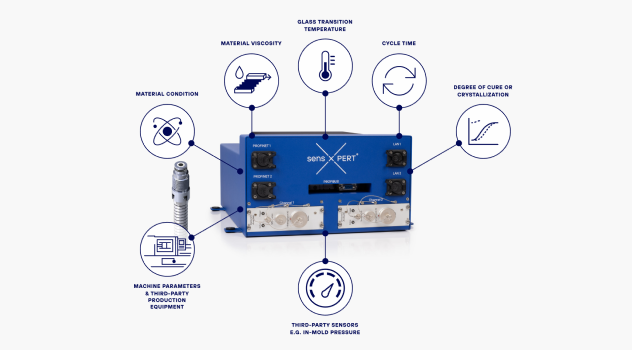

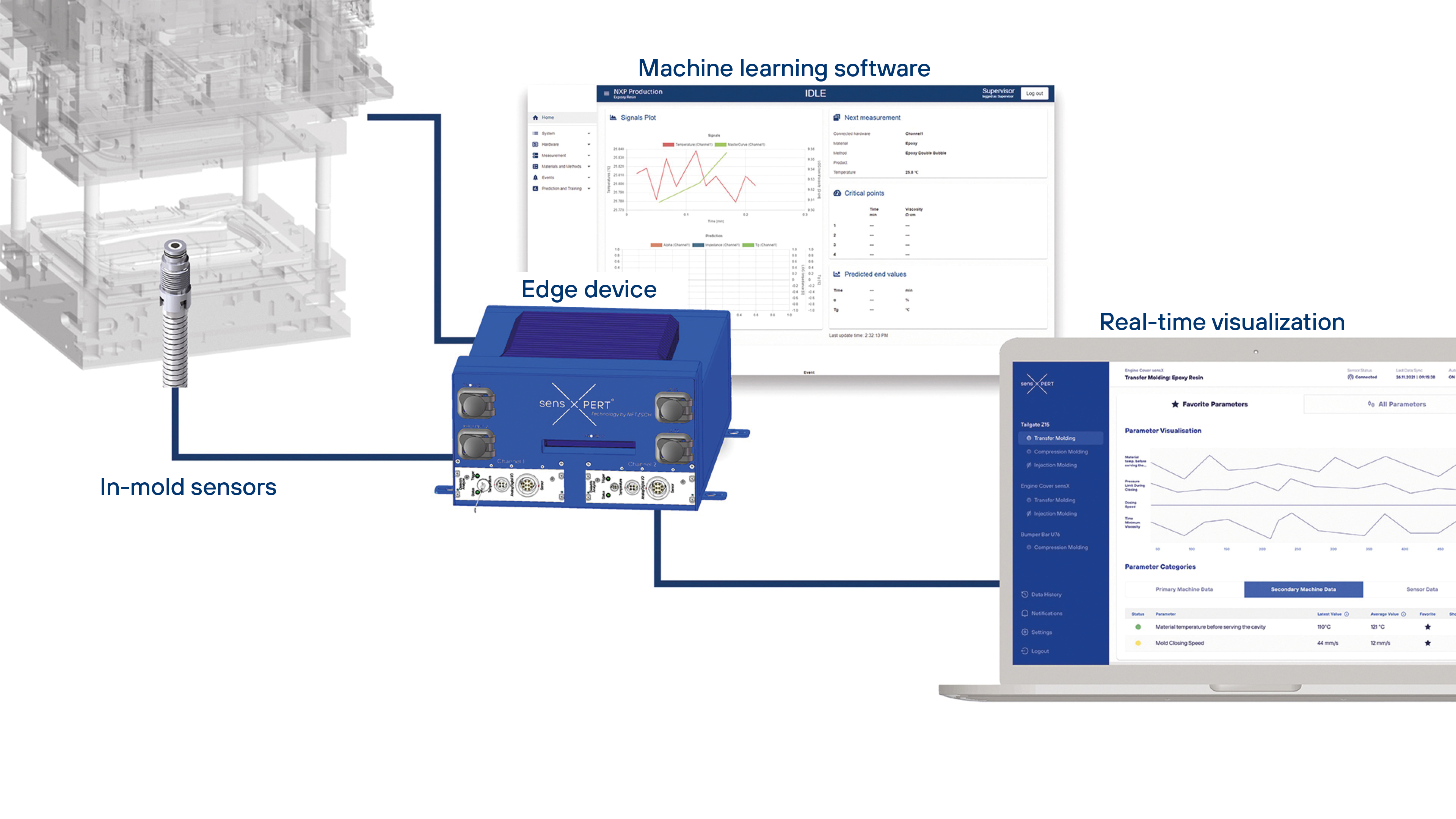

The complete sensXPERT product solution

Maximize your manufacturing profit with sensXPERT

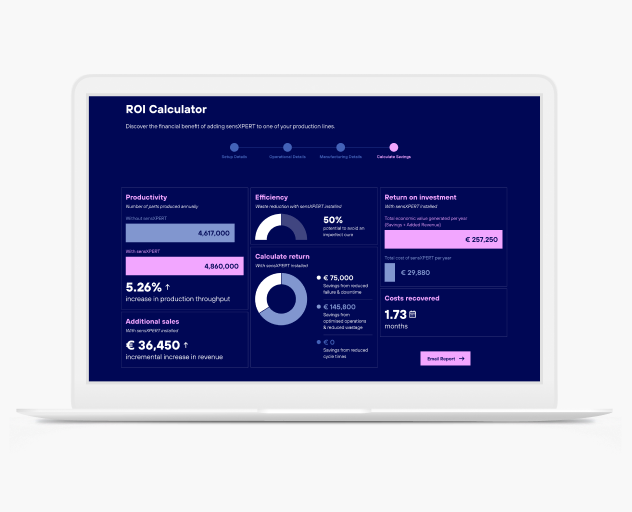

Calculate the real value of sensXPERT to your manufacturing business

Considering sensXPERT for your business? Use our powerful ROI calculator, and see how much of a return this could make for your business.

Launch ROI CalculatorGet in touch

Thank you for reaching out to us!

We will get back to you with a response as soon as possible. We are looking forward to chatting soon.

Watch our free webinars

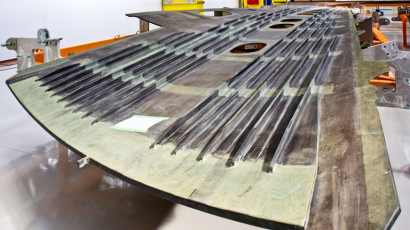

Quality and Efficiency in Aviation: The Technology That Learned to Control

How does a cutting-edge measurement technology evolve into a solution that drives real-time insights and transforms quality control and efficiency in aviation manufacturing?

Escape the Status Quo with Cutting-Edge Plastics Process Optimization

Explore how to overcome the top concerns in plastics process optimization and turn hesitation into innovation and efficiency.

Beyond Kinetic Models: Innovative Pathways to Boost Production Efficiency

Watch part 2 of our free master class. Our experts explain innovative pathways to boost production efficiency.

From Lab to Production Line: Unraveling the Truth Behind Kinetic Models

Watch part one of our free master class on kinetic models.

The Future of Dynamic and Interactive Material Data Sheets

In-mold material data in real-time allows for a new generation of material data sheets based on varying and industrial production environments.

Enabling Automated Quality Control in Composites

As industries advance new bio-based, faster reacting and increased recycled content materials and faster processes, how can manufacturers quickly establish and maintain quality control?

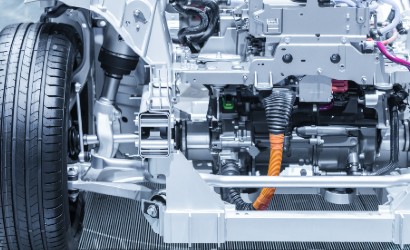

Digitizing Automotive Composite Manufacturing Using Real-Time Material Characterization

Put material knowledge at the heart of process enhancement: How to digitze automotive composite manufacturing

Paving the Way Towards Sustainable Part Production

Exploiting energy savings and waste reduction potentials supports customers in reaching ESG goals and achieving more sustainable composite part production processes

How to Boost Efficiency and Digitalize The Production of Composite Parts

Learn how an aerospace company validated the benefits of digitizing a well-established manufacturing process with sensor-based and data-driven technology

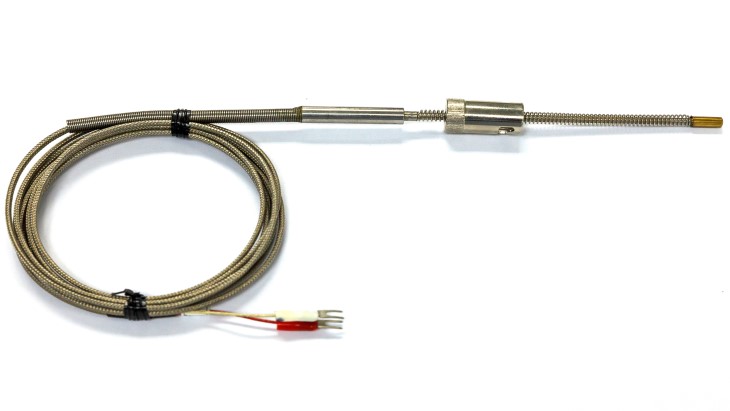

Real-Time Process Optimization With In-Mold Sensors and Machine Learning

Learn how to make plastics manufacturing more predictable with new technology

Process Optimization of Electronics Encapsulation with Reactive Thermosets

Learn how a global automotive supplier achieved up to 8% cycle time reduction in a short cycle process

Ever-Changing Plastics Industry: Trends, Materials and the Need for Adopting Smart Manufacturing Solutions

Get introduced to market and process dynamics of the plastics industry that requires the adoption of smart manufacturing solutions as well as a collaborative mindset

Breaking the Mold

Rewatch our global launch event, and discover manufacturing opportunities that were once considered impossible, but can now be implemented cost-effectively and efficiently

Tackling Plastics Manufacturing Challenges in Real-Time with sensXPERT Digital Mold

Transforming molds to become direct production communicators in various industries to solve plastics manufacturing challenges

Demystifying AI in Plastics Manufacturing

Transforming domain knowledge into business value through real-time process optimization

Revolutionizing in-situ polymerization with AI and smart machines

Usage of AI and smart machines for in-situ polymerization of lightweight fiber-reinforced polyamide 6 parts