Airbus

The aviation industry is immense, with the number of global aircraft units having been 25,578 in 2022. [1] This number is projected to rise to 38,189 units by 2032. [1] Therefore, addressing challenges and ensuring efficiency in aerospace part manufacturing is of particular importance. In this case study, a collaboration between NETZSCH Process Intelligence GmbH and a leader in the aviation industry explores the effects of process digitization on production efficiency.

Industry Status Quo

With the rise of Industry 4.0, the manufacturing industry as a whole is striving to digitize production and operations. Implementing cloud technology, artificial intelligence, robotics, sensors, and similarly disruptive technologies enables manufacturers to improve processes and keep up efficient production.

The implementation of new technology calls for the skills necessary to oversee and handle it. Besides a need to digitize, skilled labor shortages are a challenge confronting manufacturers. There is a growing need for a workforce that is proficient in automation, robotics, engineering and other necessary industry-related skills.

On account of rising demands and market pressure, manufacturers are also particularly concerned with optimizing processes in order to produce more yet maintain quality. In the plastics industry, specifically in part production, this means an attempt to shorten cycle times, save time, energy and costs, as well as reduce scrap rates. However, many manufacturers are hindered in their pursuit of these goals by a lack of process transparency and limited insight on in-mold material behavior.

The aerospace manufacturing industry often produces considerably large parts, meaning that cycle times are generally longer to ensure part quality and avoid defects. Therefore, in light of the above-mentioned challenges, the question of whether digitization can help improve efficiency in aviation part production has become a significant matter of investigation.

Leader in Aerospace Manufacturing

With the aim of investigating the effects of process digitization on production efficiency, a leader in aerospace manufacturing implemented the in-mold process monitoring system by NETZSCH Process Intelligence GmbH. Otherwise known as sensXPERT Digital Mold, the process monitoring system examined the in-mold material behavior of composite aerospace parts to detect potential deviations and avoid part rejection in post-process quality assurance (QA) tests.

Composite Part Specifications

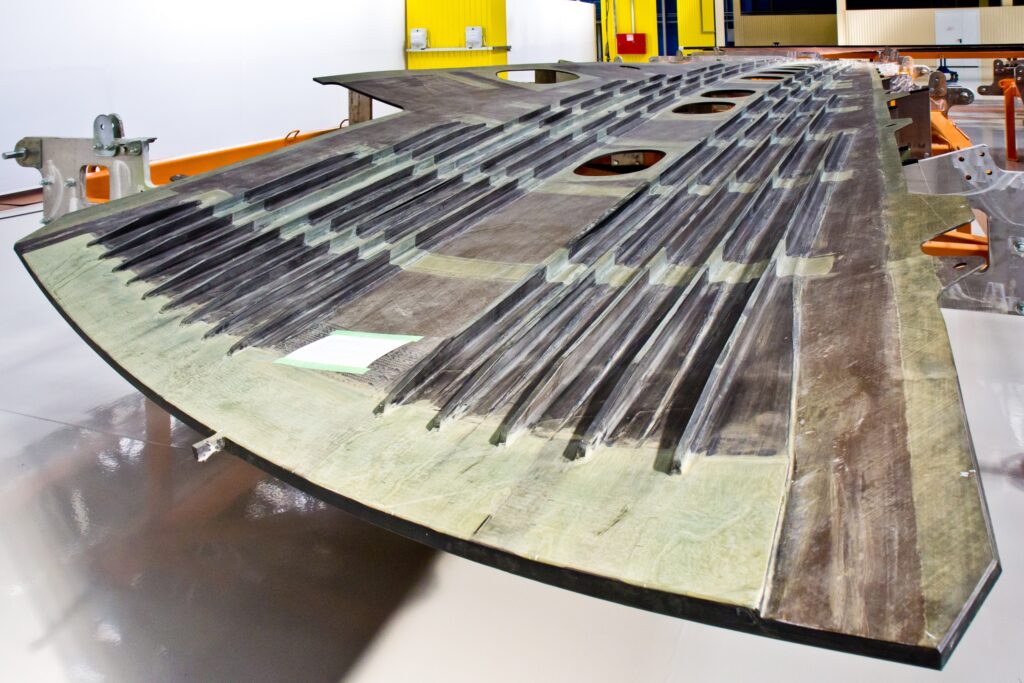

The monitored composite part is used for fuselage support and is composed of woven carbon fibre fabrics infused with RTM6-1 (HexFlow® by Hexcel Corp. [2]). RTM6-1 is a type of aerospace-grade epoxy. This material combination is typically used in the aviation industry, specifically in (vacuum-assisted) resin transfer molding, or (VA)RTM for short. This specific part is large and has different thickness-levels throughout its structure. During initial investigations, 45 fuselage support parts were produced using sensXPERT Digital Mold.

Manufacturing Insight

Two major processes are involved in the production of the aerospace parts, namely VARTM and autoclave. In order to effectively cure the parts, VARTM is conducted with a target Degree of Cure (DoC) of 80%, and the post-mold autoclave process with a 95% secondary DoC target. Between the VARTM and autoclave cycles, a cool-down, or hold, period is carried out.

VARTM is a process in which a vacuum is applied in resin transfer molding. To start, the aviation part manufacturer cuts dry-fiber preforms and manually places them into the molding tool. After closing the mold, two components – the epoxy polymer and a hardener – are combined and injected into the mold. The average cycle time for VARTM is about 110 minutes (~ 2 hours). As a means of avoiding deformation and stress on the part during demolding, a slow cure at low temperatures is implemented.

When VARTM is completed, the parts are at a temperature of about 150°C and take several hours to reach a safe enough temperature for demolding. Therefore, the cool-down/hold period is a necessary step in the production of these parts. During the cool-down period, the parts continue to cure. When they reach temperatures of about 50°C or lower, they can be safely demolded and will have reached a DoC of at least 80%.

The final process in the molding of these parts is autoclave curing. In this part of the process, several parts enter an autoclave. The molding cycle only begins once the autoclave chamber is filled. Once this cycle starts, the parts are exposed to predetermined pressure and temperature levels to attain a target DoC of around 95%.

The Problem

The entire manufacturing process consists of long cycles and hold periods to prevent scrap and defective parts. Generally, manufacturers implement longer cycles to guarantee reaching their desired DoC. A couple of reasons for this are limited insight into in-mold material behavior and a lack of process transparency. However, longer cycles result in greater energy expenditure, higher costs, and overall slower production. These difficulties can be countered by digitizing manufacturing processes and wielding data to improve efficiency.

The Solution

The sensXPERT Digital Mold comes into play where digitization and real-time material characterization data can help eliminate a problem. This sensor technology was developed to reliably predict in-mold material behavior and help manufacturers implement dynamic process adaptation in their production cycles. sensXPERT provides accurate insight into optimal cycle end-times based on desired DoC targets.

How it works…

The sensXPERT system is comprised of four main components; dielectric sensors, an accompanying Edge Device, an interface to the Edge Device (WebApp), and cloud accessibility. The dielectric sensors are positioned in the mold and can withstand a range of pressures and temperatures. Compatible with several manufacturing processes – including but not limited to (reaction) injection molding, VARTM and autoclave curing – the sensors can measure the behavior of various materials, such as thermosets, thermoplastics, rubber, fiber-reinforced polymers, and more.

When using sensXPERT, manufacturers gain insight into several in-mold material and process parameters throughout the entire cycle. Examples include,

- Degree of Cure (DoC),

- Percent polymerization,

- Glass-transition temperature (Tg),

- Viscosity and flow-front position,

- Temperature inside the mold,

- and material deviations – which can be caused by aging, out-of-spec material, the presence of contaminants, pre-molding storage conditions, etc.

The sensors are connected to an edge device that is positioned outside, but nearby, the mold. An all-in-one powerful IPC and dielectric analyzer, the edge device collects all machine data and process parameters. The WebApp then visualizes all active processes and implements machine learning (ML) and predictive algorithms to determine the optimal point of cure. In doing so, manufacturers are able to view and adapt their processes in real-time.

Additionally, all data collected by the edge device is transferred to a manufacturer’s sensXPERT Digital Cloud Service account following a completed production cycle. On the Cloud, all collected data is stored, visualized, and compared with historical process data to assess various quality indicators. Cloud data is also used to train ML algorithms and optimize them for process outcome predictions on the edge device.

All in all, the entire sensXPERT system ensures the digitization of and full transparency in molding cycles. Part processors can use sensXPERT to account for optimal curing points and potential in-situ process or material behavior deviations. Now that QA testing has moved upstream and is performed within the mold, manufacturers gain more process stability and can avoid final part defects.

sensXPERT X Aviation Results

To train the predictive algorithm – specific to this aviation part manufacturer’s process -, data from 20 production cycles was collected and used to train an ML model. Using the dielectric sensors, sensXPERT collected temperature data for several minutes to calculate the DoC via a kinetic model.

A way of mathematically describing chemical reactions at specific temperatures, a kinetic model presents the speed of cure and is used by sensXPERT to determine the optimal point of cure.

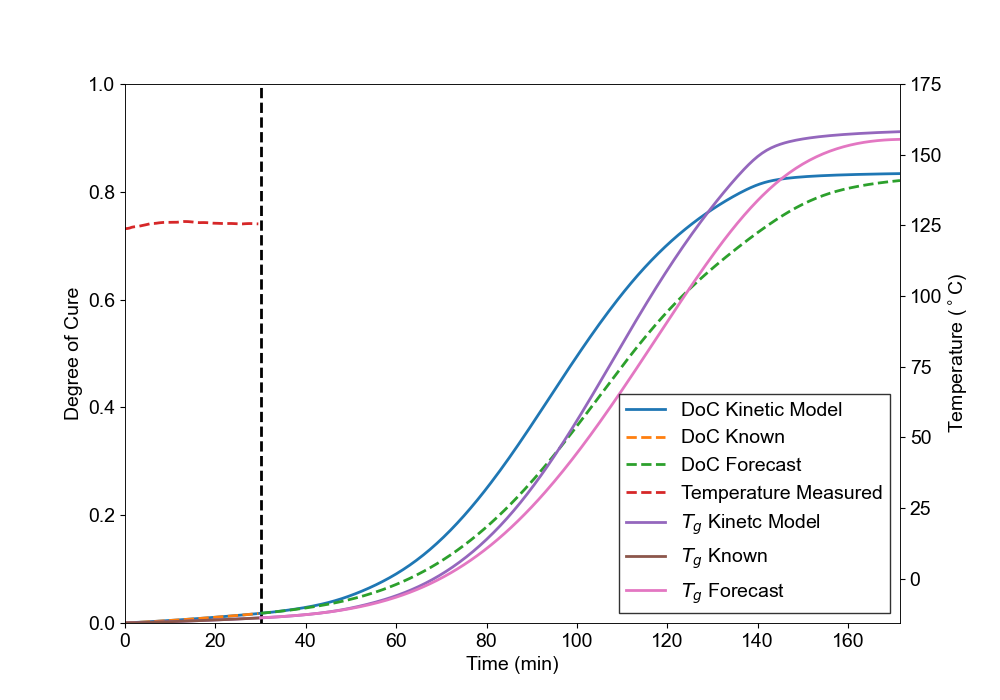

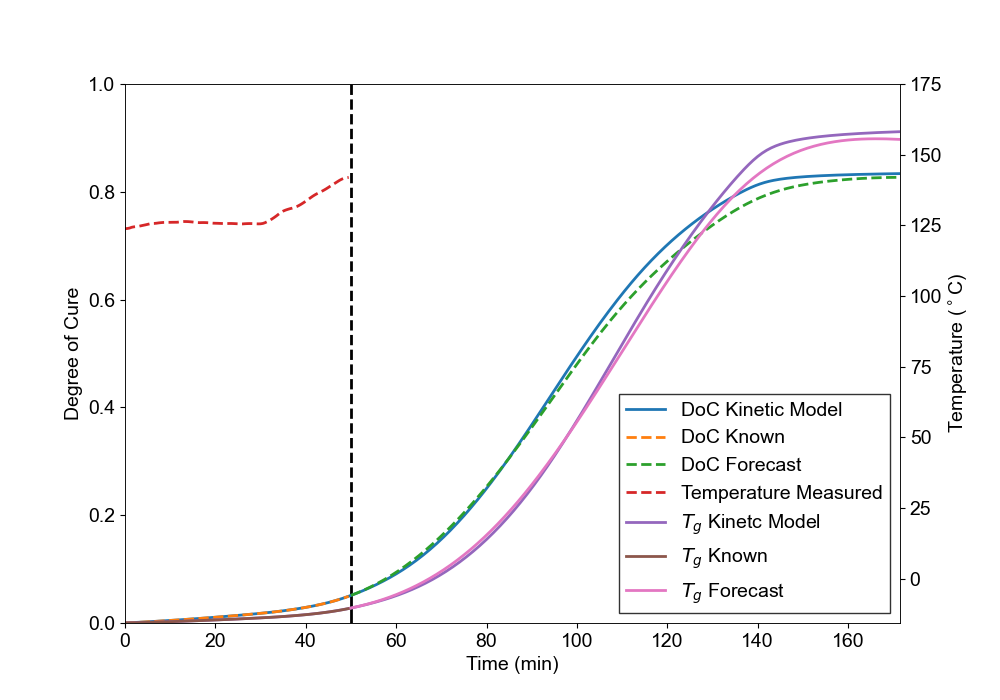

Correspondingly, the ML model is trained to forecast process curing outcomes. Following a completed cycle, the ML model’s forecast was compared to the DoC calculated using a kinetic model. This was done to ensure accuracy and validity in the predictions. Figure 1 illustrates how the longer a process is measured the more accurate its prediction becomes. In this case, after 20 to 50 minutes of measurements, sensXPERT could accurately forecast the outcome of the cycle. Furthermore, as predictions develop in real-time, new data is promptly fed into the ML model. Thus, the model is constantly updated.

Figure 1 depicts predictions for DoC and Tg. The forecast is compared to the kinetic model. Top: Forecast for DoC and Tg after 30 min. Bottom: Forecast for DoC and Tg after 45 min.

In this production process, DoC and Tg were the outcomes used to predict part performance. However, for greater prediction accuracy, additional factors, such as temperature and impedance were inputs for the ML algorithm.

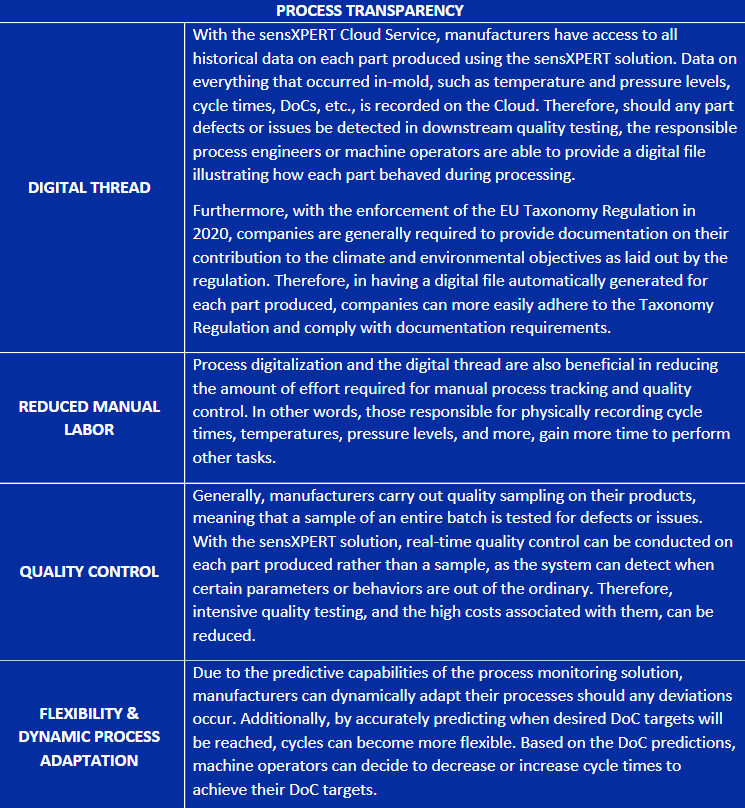

Through their collaboration with sensXPERT, the aviation company gained transparency in their processes and, consequently, production data that enabled overall process optimization. By improving their process transparency, the aviation company also came by four major benefits, namely a digital thread per part produced, reduced manual labor, strengthened quality control, and cycle flexibility.

Conclusion

Overall, the sensXPERT process monitoring system allowed for real-time process adaptation, especially with the advantage of only needing up to 50 minutes to forecast the rest of the cycle. sensXPERT created an opportunity for process visualization and the ability to remedy deviated parts before they moved downstream. Flexibility in the cool-down/post-curing period was another added benefit. Furthermore, an advantage of Digital Mold lies in its creation of a digital thread for each part produced, which is beneficial for quality control and general reporting.

The aviation company was able to digitize its manufacturing process, gain real-time process insights, and secure historical data on each and every one of the parts produced in collaboration with sensXPERT. This case revealed that more complicated production cycles with various production stages – such as the ones carried out in aerospace part manufacturing – can be equipped with technology that generates greater process understanding, efficiency, and transparency.

Digitizing manufacturing processes with sensXPERT Digital Mold leads to a number of advantages, some of which are,

- Cycle time reduction

- Scrap Reduction

- Lower energy usage

- In-mold transparency

- Cost control

- Efficient production

- Digital thread that offers traceability on each part produced

This technology prepares manufacturers to meet market demands, as well as keep up with industrial evolutions, such as Industry 4.0.