Our contributions to the automotive industry

Our Solution

Tomorrow’s Technology Here Today

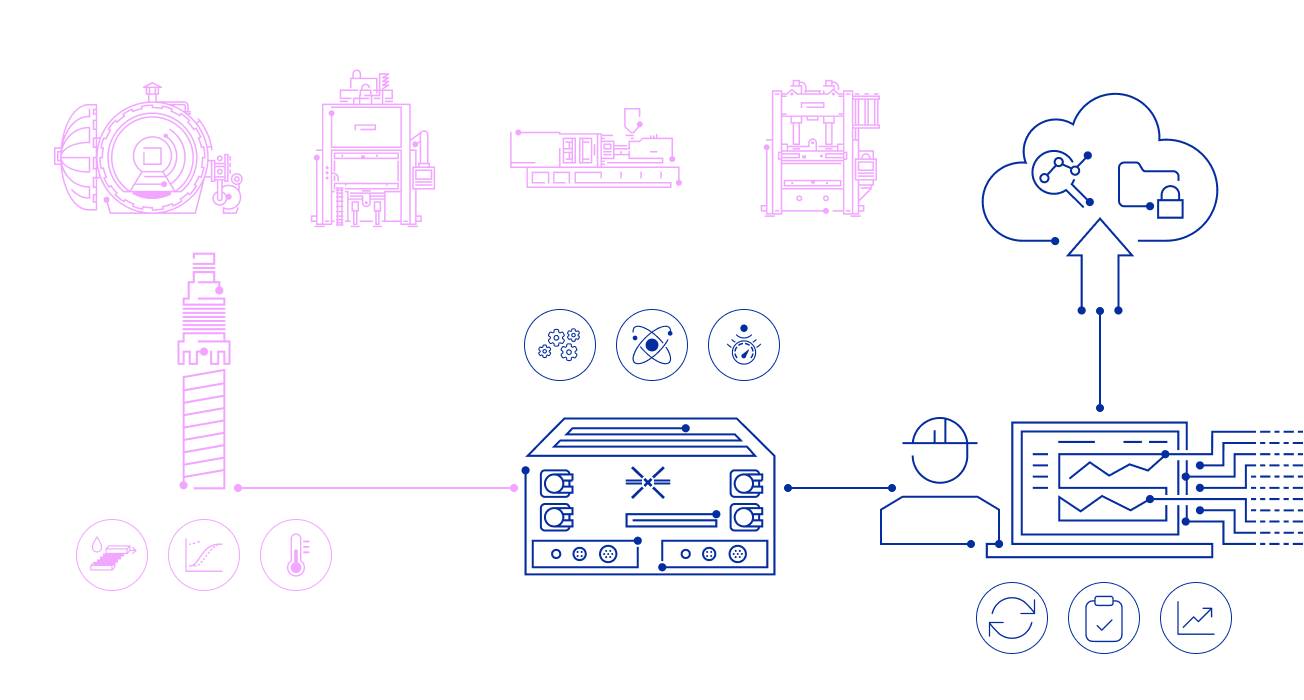

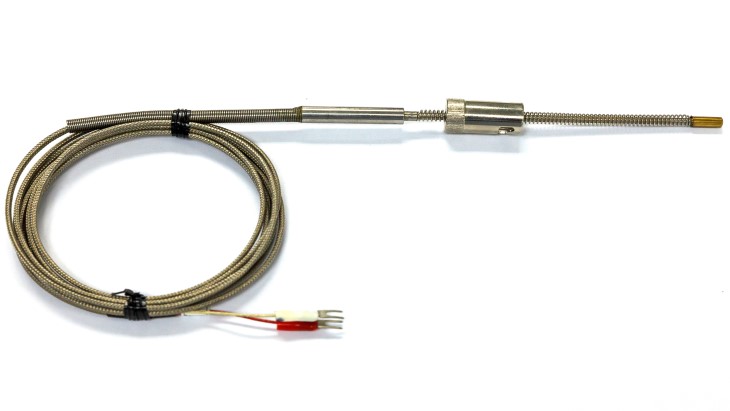

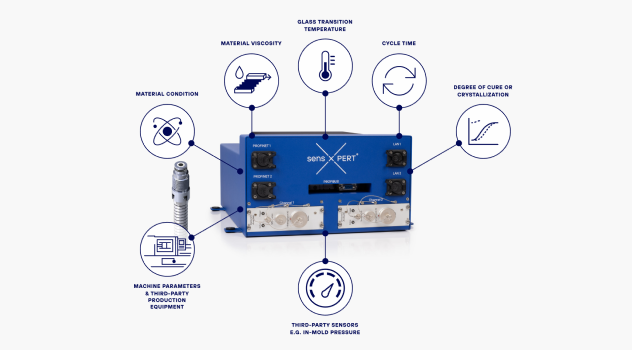

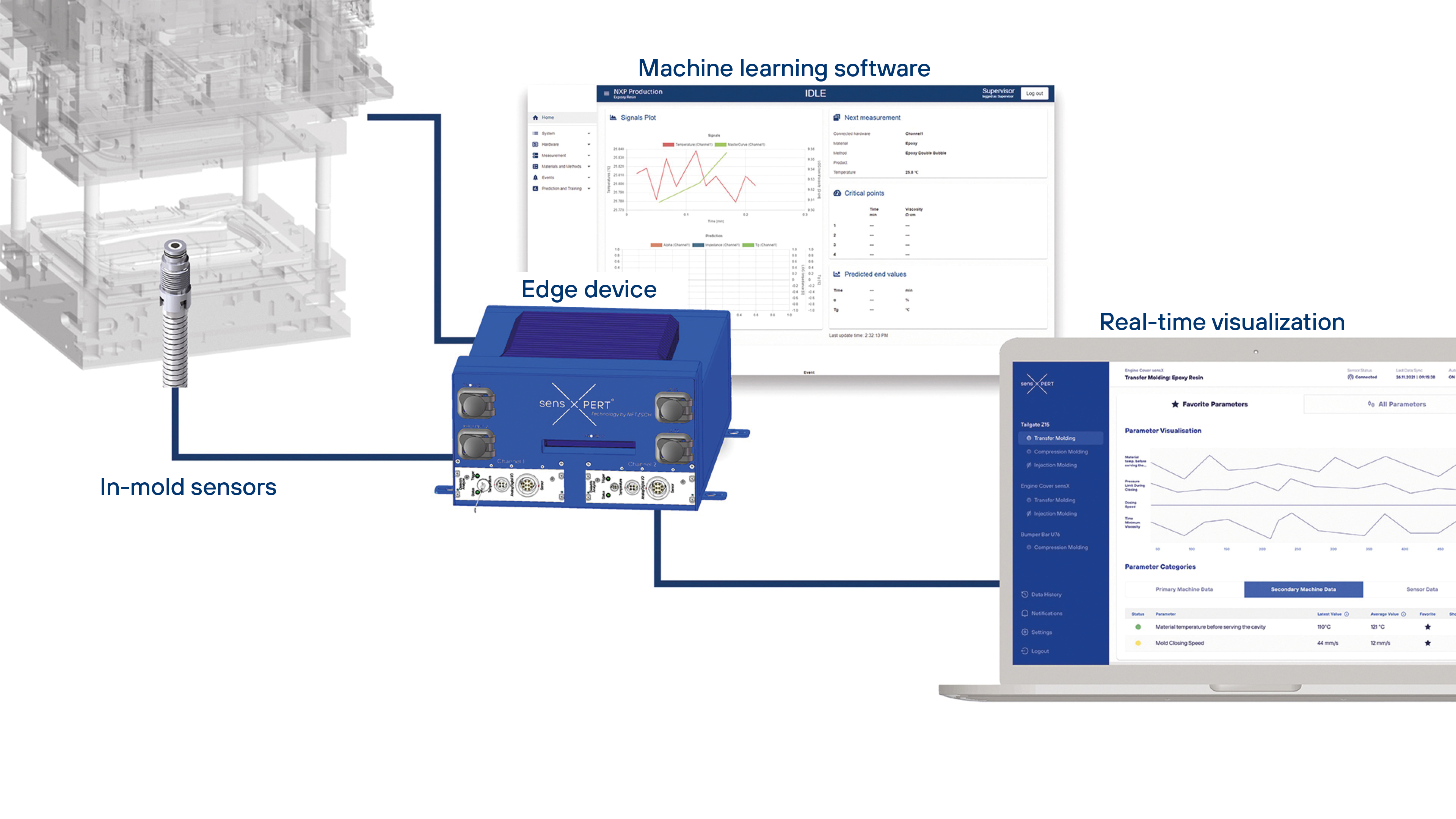

sensXPERT revolutionizes composite production with its advanced process control technology. By providing real-time monitoring and analysis of critical material properties like ion viscosity and gel point, our system enables early defect detection and dynamic cycle adjustments. Enhanced quality control, increased production efficiency, and the ability to achieve lightweighting goals. sensXPERT's Digital Mold Solution sets the standard for excellence in composite manufacturing. Experience data-driven decision-making and unlock your production's full potential with sensXPERT.

sensXPERT Digital MoldKey Benefits of our Solution

Improve process R&R, bring products to market faster at lower cost.

Up to 50% scrap reduction

Shorter processes means fewer tools or tools with fewer cavities are needed for each program. This reduces indirect costs and means molds can be produced in less time.

Up to 23% increase in energy savings

Faster and more consistent cycles, lower energy usage, and less waste lowers direct costs while helping manufacturers bring products to market faster.

High R&R no matter the Location

To supply global platforms, processes must be controlled, consistent, and traceable regardless of location, lowering the cost of quality and reducing supply-chain issues.

The complete sensXPERT product solution

Webinar

Digitizing Automotive Composite Manufacturing Using Real-Time Material Characterization

Put material knowledge at the heart of process enhancement: How to digitze automotive composite manufacturing. This webinar presents how dielectric sensors, machine learning, and material models are combined to provide live monitoring, prediction, and optimization during the manufacturing process for each individual part.

Watch WebinarYour Return of Investment

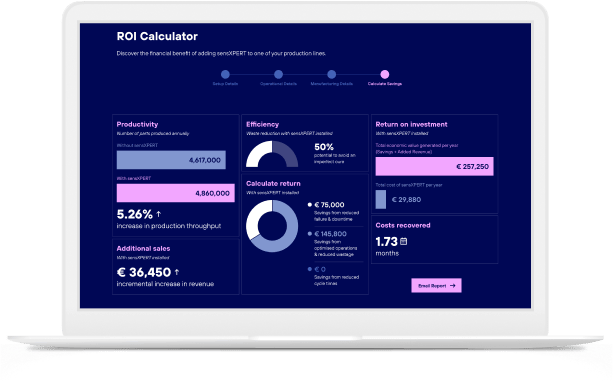

ROI Calculator

Calculate the real value of sensXPERT for your manufacturing business

Considering sensXPERT for your business? Use our powerful ROI calculator and see how much of a return this could make for your business.

Launch ROI calculatorGet in touch

Ready to streamline your automotive composite production? Contact us today!

Thank you for reaching out to us!

We will get back to you with a response as soon as possible. We are looking forward to chatting soon.